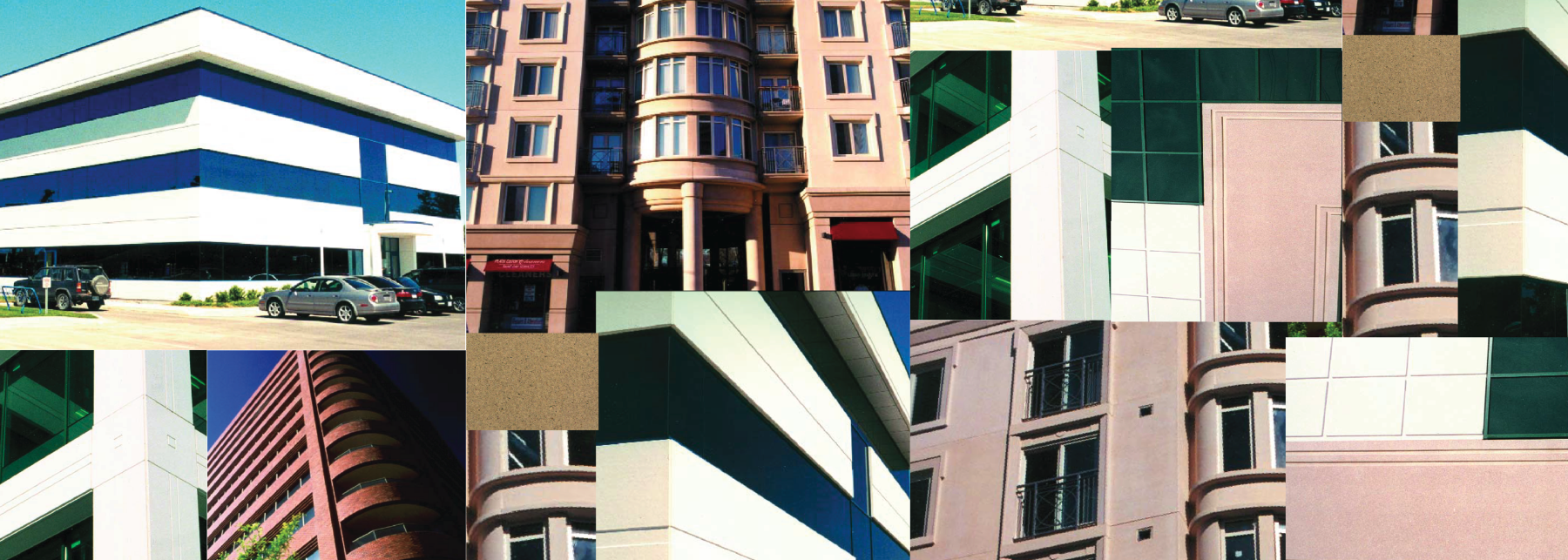

Most people associate concrete with the colour grey. This is because driveways, patios and sidewalks often feature this colour. However, concrete can be manufactured in shades other than grey. In fact, an entire universe of colour is achievable. Architectural precast concrete remains exposed when installed, and it can be produced in almost any colour, finish or texture imaginable.Elements for producing concrete or veneer material determine the colour and texture of the concrete. Achieving consistent results with TKL’s coloured precast concrete requires a high level of skill and precision. Our team of pre-casters will implement the quality control measures necessary to consistently manufacture coloured precast concrete. Here’s what goes into making TKL’s coloured precast concrete.

The Concrete Mix

A concrete mix is achieved by mixing and placing all the concrete meant for use on the exposed side of a piece. This is done at once to reduce the number of variances within a panel. A “face mix” is employed to reduce the amount of concrete required to pull this off.

To avoid cold joints, a point of weakness caused by delays or interruptions in the concreting operations, TKL precast concrete is placed quickly. This is done while at the same time keeping drop heights as low as possible.

Paste Dominant Colour

To achieve a smooth and light exposure finish, such as an abrasive blasted finish, a mild acid-etched finish, or a form finish, use the paste as the primary colour. The colour is a result of a combination of pigments, water and cement.

Cement is hydrated using a chemical process to produce the paste. Consequently, the resultant colour is highly susceptible to cement type, form materials, temperature, curing techniques and water-cementitious (w/c) ratio. To minimize colour variations, TKL makes sure that fluctuations of these variables from one batch to another do not occur.

Pigments

Pigments are known to change the colour of the concrete paste. Iron oxides are commonly used to make pigments since they produce stable hues that last. Black, red, and yellow is the primary iron oxide colours. The reds have an orange or blue tint. One can combine these colours to create a plethora of different hues or shades. You can also get other colours such as blues from cobalt and greens from chromium oxides. These pigments function well. However, they are more expensive than the commonly used iron oxides.

Water

Always keep the water-cementitious ratio at a low, stable level to allow colour consistency. Low water-cementitious ratios improve the uniformity of colour. Colour streaking and colour variation can be exacerbated by high w/c ratios. Slight changes in temperature, curing methods and water-cementitious ratios can significantly affect the consistency of the colour of the paste.

Design and Location

When deciding on colour and finish choices, TKL replicates the conditions under which the product will be viewed in its final position.

After installation, most people do not view structures at close range. For instance, a panel on the 6th floor is viewed from approximately 70 feet and from underneath. As a result, the finish and colour may appear different from a distance compared to standing in front of it. When choosing a finish, view the samples from several distances and angles, from afar and up close.

The design and final installation site influence how colour is perceived. Light, density, weather, and other surrounding elements influence the colour tone and the perception of a colour shade. For example, a white precast finish paired with black window glazing has a different visual effect compared to when paired with gold window glazing.

Deep exposure of aggregates sometimes results in shadows that darken brighter colours, but this is not as noticeable on a cloudy day. Using larger samples and viewing them under varied settings aids in achieving the desired architectural finish and colour outcomes.

With years of experience manufacturing precast concrete products, TKL brings out different colour shades and hues as accurately as possible. We make sure your structure is not only durable but also visually appealing.